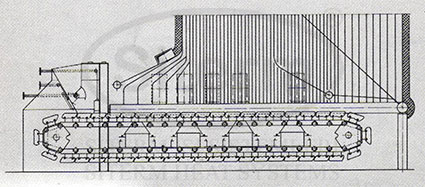

Water-tube boilers produced by Siterm work perfectly and safely under high pressure. The boiler consists of one or two drums and has a steel construction structure.

The boiler is comprised of drum, front, rear and side walls, an optional echo and superheater. The walls are composed of diaphragm panels.

These membrane walls are made in, our fully automated, TÜV approved submerged panel manufacturing machine designed through our company.

Drum is not exposed to direct flame for safe use of the water-tube boiler. The flame directly penetrates the, the diaphragm walls consisting of pipe-sheet bar-pipe. This allows use in a safe way without any risk of explosion.

Diaphragm walls of the boiler are completely welded and no refractors are used on the walls (except for the burner inlet). This provides the receipt of highest efficiency from the walls. These walls are strengthened with metal bandages due to the height of the boiler.

The control of this type of boilers is made by PLC and SCADA in a fully automated manner.

All units are isolated and are delivered with galvanized trapezoidal-shaped metal sheets. These metal sheets can be painted according to customer requirements.

A superheater can be assembled easily to these type of boilers superheated in order to meet the steam request of our esteemed clientele. According to customer requirements one or two superheaters provide perfect steam quality.

The boiler is compatible to work with fuel oil, diesel and natural gas. According to customer request combustion chamber can also be designed to burn coal.

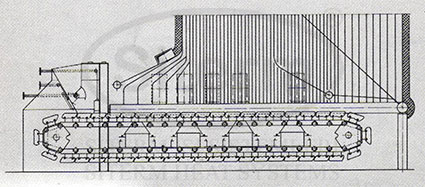

Water-tube boilers produced by Siterm work perfectly and safely under high pressure. The boiler consists of one or two drums and has a steel construction structure.

The boiler is comprised of drum, front, rear and side walls, an optional echo and superheater. The walls are composed of diaphragm panels.

These membrane walls are made in, our fully automated, TÜV approved submerged panel manufacturing machine designed through our company.

Drum is not exposed to direct flame for safe use of the water-tube boiler. The flame directly penetrates the, the diaphragm walls consisting of pipe-sheet bar-pipe. This allows use in a safe way without any risk of explosion.

Diaphragm walls of the boiler are completely welded and no refractors are used on the walls (except for the burner inlet). This provides the receipt of highest efficiency from the walls. These walls are strengthened with metal bandages due to the height of the boiler.

The control of this type of boilers is made by PLC and SCADA in a fully automated manner.

All units are isolated and are delivered with galvanized trapezoidal-shaped metal sheets. These metal sheets can be painted according to customer requirements.

A superheater can be assembled easily to these type of boilers superheated in order to meet the steam request of our esteemed clientele. According to customer requirements one or two superheaters provide perfect steam quality.

The boiler is compatible to work with fuel oil, diesel and natural gas. According to customer request combustion chamber can also be designed to burn coal.